#include "DSP2833x_Device.h" // DSP2833x Headerfile Include File

#include "DSP2833x_Examples.h" // DSP2833x Examples Include File

#include "DSP28x_Project.h" // Device Headerfile and Examples Include File

// PWM start parameters

Uint16 *ExRamStart = (Uint16 *)0x100000;

void InitEPwm1Example(void);

void InitEPwm2Example(void);

void InitEPwm3Example(void);

void Adcsample(void);

Uint32 EPwm1TimerIntCount;

Uint32 EPwm2TimerIntCount;

Uint32 EPwm3TimerIntCount;

Uint16 EPwm1_DB_Direction;

Uint16 EPwm2_DB_Direction;

Uint16 EPwm3_DB_Direction;

#include "DSP2833x_Examples.h" // DSP2833x Examples Include File

#include "DSP28x_Project.h" // Device Headerfile and Examples Include File

// PWM start parameters

Uint16 *ExRamStart = (Uint16 *)0x100000;

void InitEPwm1Example(void);

void InitEPwm2Example(void);

void InitEPwm3Example(void);

void Adcsample(void);

Uint32 EPwm1TimerIntCount;

Uint32 EPwm2TimerIntCount;

Uint32 EPwm3TimerIntCount;

Uint16 EPwm1_DB_Direction;

Uint16 EPwm2_DB_Direction;

Uint16 EPwm3_DB_Direction;

#define EPWM1_MAX_DB 0x03FF

#define EPWM2_MAX_DB 0x03FF

#define EPWM3_MAX_DB 0x03FF

#define EPWM2_MAX_DB 0x03FF

#define EPWM3_MAX_DB 0x03FF

#define EPWM1_MIN_DB 0

#define EPWM2_MIN_DB 0

#define EPWM3_MIN_DB 0

#define EPWM2_MIN_DB 0

#define EPWM3_MIN_DB 0

#define DB_UP 1

#define DB_DOWN 0

#define DB_DOWN 0

// ADC start parameters

#if (CPU_FRQ_150MHZ) // Default – 150 ===========================================================================================================================MHz SYSCLKOUT

#define ADC_MODCLK 0x3 // HSPCLK = SYSCLKOUT/2*ADC_MODCLK2 = 150/(2*3) = 25.0 MHz

#endif

#if (CPU_FRQ_100MHZ)

#define ADC_MODCLK 0x2 // HSPCLK = SYSCLKOUT/2*ADC_MODCLK2 = 100/(2*2) = 25.0 MHz

#endif

#define ADC_CKPS 0x0 // ADC module clock = HSPCLK/1 = 25.5MHz/(1) = 25.0 MHz

#define ADC_SHCLK 0x1 // S/H width in ADC module periods = 2 ADC cycle

#define AVG 1000 // Average sample limit

#define ZOFFSET 0x00 // Average Zero offset

#define BUF_SIZE 512 // Sample buffer size

#if (CPU_FRQ_150MHZ) // Default – 150 ===========================================================================================================================MHz SYSCLKOUT

#define ADC_MODCLK 0x3 // HSPCLK = SYSCLKOUT/2*ADC_MODCLK2 = 150/(2*3) = 25.0 MHz

#endif

#if (CPU_FRQ_100MHZ)

#define ADC_MODCLK 0x2 // HSPCLK = SYSCLKOUT/2*ADC_MODCLK2 = 100/(2*2) = 25.0 MHz

#endif

#define ADC_CKPS 0x0 // ADC module clock = HSPCLK/1 = 25.5MHz/(1) = 25.0 MHz

#define ADC_SHCLK 0x1 // S/H width in ADC module periods = 2 ADC cycle

#define AVG 1000 // Average sample limit

#define ZOFFSET 0x00 // Average Zero offset

#define BUF_SIZE 512 // Sample buffer size

// Prototype statements for functions found within this file.

__interrupt void adc_isr(void);

__interrupt void adc_isr(void);

// Global variables used in this example:

Uint16 LoopCount;

Uint16 ConversionCount;

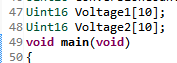

Uint16 Voltage1[10];

Uint16 Voltage2[10];

void main(void)

{

Uint16 LoopCount;

Uint16 ConversionCount;

Uint16 Voltage1[10];

Uint16 Voltage2[10];

void main(void)

{

// Step 1. Initialize System Control:

// PLL, WatchDog, enable Peripheral Clocks

// This example function is found in the DSP2833x_SysCtrl.c file.

int i;

InitSysCtrl();

// PLL, WatchDog, enable Peripheral Clocks

// This example function is found in the DSP2833x_SysCtrl.c file.

int i;

InitSysCtrl();

// Step 2. Initalize GPIO:

// This example function is found in the DSP2833x_Gpio.c file and

// illustrates how to set the GPIO to it's default state.

// InitGpio(); // Skipped for this example

InitEPwm1Gpio();

InitEPwm2Gpio();

InitEPwm3Gpio();

//zq

// Step 3. Clear all interrupts and initialize PIE vector table:

// Disable CPU interrupts

DINT;

// This example function is found in the DSP2833x_Gpio.c file and

// illustrates how to set the GPIO to it's default state.

// InitGpio(); // Skipped for this example

InitEPwm1Gpio();

InitEPwm2Gpio();

InitEPwm3Gpio();

//zq

// Step 3. Clear all interrupts and initialize PIE vector table:

// Disable CPU interrupts

DINT;

// Initialize the PIE control registers to their default state.

// The default state is all PIE interrupts disabled and flags

// are cleared.

// This function is found in the DSP2833x_PieCtrl.c file.

InitPieCtrl();

// The default state is all PIE interrupts disabled and flags

// are cleared.

// This function is found in the DSP2833x_PieCtrl.c file.

InitPieCtrl();

// Disable CPU interrupts and clear all CPU interrupt flags:

IER = 0x0000;

IFR = 0x0000;

IER = 0x0000;

IFR = 0x0000;

// Initialize the PIE vector table with pointers to the shell Interrupt

// Service Routines (ISR).

// This will populate the entire table, even if the interrupt

// is not used in this example. This is useful for debug purposes.

// The shell ISR routines are found in DSP2833x_DefaultIsr.c.

// This function is found in DSP2833x_PieVect.c.

InitPieVectTable();

// Service Routines (ISR).

// This will populate the entire table, even if the interrupt

// is not used in this example. This is useful for debug purposes.

// The shell ISR routines are found in DSP2833x_DefaultIsr.c.

// This function is found in DSP2833x_PieVect.c.

InitPieVectTable();

EALLOW; // This is needed to write to EALLOW protected register

PieVectTable.ADCINT = &adc_isr;

EDIS; // This is needed to disable write to EALLOW protected registers

PieVectTable.ADCINT = &adc_isr;

EDIS; // This is needed to disable write to EALLOW protected registers

InitAdc(); // For this example, init the ADC

// Interrupts that are used in this example are re-mapped to

// ISR functions found within this file.

// ISR functions found within this file.

// StartCpuTimer0();

EALLOW;

SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 0;

EDIS;

Adcsample();

InitEPwm1Example();

InitEPwm2Example();

InitEPwm3Example();

EALLOW;

SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 0;

EDIS;

Adcsample();

InitEPwm1Example();

InitEPwm2Example();

InitEPwm3Example();

EALLOW;

SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 1;

EDIS;

EALLOW;

SysCtrlRegs.HISPCP.all = ADC_MODCLK; // HSPCLK = SYSCLKOUT/ADC_MODCLK

EDIS;

SysCtrlRegs.PCLKCR0.bit.TBCLKSYNC = 1;

EDIS;

EALLOW;

SysCtrlRegs.HISPCP.all = ADC_MODCLK; // HSPCLK = SYSCLKOUT/ADC_MODCLK

EDIS;

// Step 5. User specific code, enable interrupts

// Initalize counters:

EPwm1TimerIntCount = 0;

EPwm2TimerIntCount = 0;

EPwm3TimerIntCount = 0;

// Initalize counters:

EPwm1TimerIntCount = 0;

EPwm2TimerIntCount = 0;

EPwm3TimerIntCount = 0;

// Enable CPU INT3 which is connected to EPWM1-3 INT:

//IER |= M_INT3;

//IER |= M_INT3;

// Enable EPWM INTn in the PIE: Group 3 interrupt 1-3

//PieCtrlRegs.PIEIER3.bit.INTx1 = 1;

//PieCtrlRegs.PIEIER3.bit.INTx2 = 1;

//PieCtrlRegs.PIEIER3.bit.INTx3 = 1;

//PieCtrlRegs.PIEIER3.bit.INTx1 = 1;

//PieCtrlRegs.PIEIER3.bit.INTx2 = 1;

//PieCtrlRegs.PIEIER3.bit.INTx3 = 1;

// Enable ADCINT in PIE

PieCtrlRegs.PIEIER1.bit.INTx6 = 1;

PieCtrlRegs.PIEIER1.bit.INTx6 = 1;

IER |= M_INT1; // Enable CPU Interrupt 1

// Enable global Interrupts and higher priority real-time debug events:

EINT; // Enable Global interrupt INTM

ERTM; // Enable Global realtime interrupt DBGM

EINT; // Enable Global interrupt INTM

ERTM; // Enable Global realtime interrupt DBGM

LoopCount = 0;

ConversionCount = 0;

ConversionCount = 0;

// Step 6. IDLE loop. Just sit and loop forever (optional):

for(;;)

{

asm(" NOP");

for(i=1;i<=10;i++)

{}

}

}

//ADC模块

void Adcsample()

{

for(;;)

{

asm(" NOP");

for(i=1;i<=10;i++)

{}

}

}

//ADC模块

void Adcsample()

{

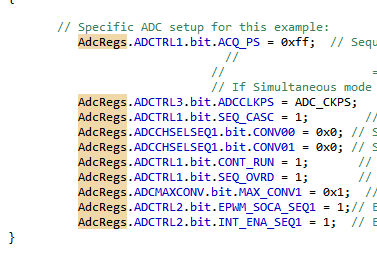

// Specific ADC setup for this example:

//AdcRegs.ADCTRL1.bit.ACQ_PS = 0xff; // Sequential mode: Sample rate = 1/[(2+ACQ_PS)*ADC clock in ns]

// = 1/(3*40ns) =8.3MHz (for 150 MHz SYSCLKOUT)

// = 1/(3*80ns) =4.17MHz (for 100 MHz SYSCLKOUT)

// If Simultaneous mode enabled: Sample rate = 1/[(3+ACQ_PS)*ADC clock in ns]

AdcRegs.ADCTRL3.bit.ADCCLKPS = ADC_CKPS;

//AdcRegs.ADCTRL1.bit.SEQ_CASC = 1; // 1 Cascaded mode

AdcRegs.ADCCHSELSEQ1.bit.CONV00 = 0x0; // Setup ADCINA3 as 1st SEQ1 conv.

AdcRegs.ADCCHSELSEQ1.bit.CONV01 = 0x0; // Setup ADCINA2 as 2nd SEQ1 conv.

//AdcRegs.ADCTRL1.bit.CONT_RUN = 1; // Setup continuous run

//AdcRegs.ADCTRL1.bit.SEQ_OVRD = 1; // Enable Sequencer override feature

AdcRegs.ADCMAXCONV.bit.MAX_CONV1 = 0x1; // convert and store in 8 results registers

AdcRegs.ADCTRL2.bit.EPWM_SOCA_SEQ1 = 1;// Enable SOCA from ePWM to start SEQ1

AdcRegs.ADCTRL2.bit.INT_ENA_SEQ1 = 1; // Enable SEQ1 interrupt (every EOS)

}

//AdcRegs.ADCTRL1.bit.ACQ_PS = 0xff; // Sequential mode: Sample rate = 1/[(2+ACQ_PS)*ADC clock in ns]

// = 1/(3*40ns) =8.3MHz (for 150 MHz SYSCLKOUT)

// = 1/(3*80ns) =4.17MHz (for 100 MHz SYSCLKOUT)

// If Simultaneous mode enabled: Sample rate = 1/[(3+ACQ_PS)*ADC clock in ns]

AdcRegs.ADCTRL3.bit.ADCCLKPS = ADC_CKPS;

//AdcRegs.ADCTRL1.bit.SEQ_CASC = 1; // 1 Cascaded mode

AdcRegs.ADCCHSELSEQ1.bit.CONV00 = 0x0; // Setup ADCINA3 as 1st SEQ1 conv.

AdcRegs.ADCCHSELSEQ1.bit.CONV01 = 0x0; // Setup ADCINA2 as 2nd SEQ1 conv.

//AdcRegs.ADCTRL1.bit.CONT_RUN = 1; // Setup continuous run

//AdcRegs.ADCTRL1.bit.SEQ_OVRD = 1; // Enable Sequencer override feature

AdcRegs.ADCMAXCONV.bit.MAX_CONV1 = 0x1; // convert and store in 8 results registers

AdcRegs.ADCTRL2.bit.EPWM_SOCA_SEQ1 = 1;// Enable SOCA from ePWM to start SEQ1

AdcRegs.ADCTRL2.bit.INT_ENA_SEQ1 = 1; // Enable SEQ1 interrupt (every EOS)

}

//PWM模块

void InitEPwm1Example()

{

{

EPwm1Regs.TBPRD =7500; // Period = 900 TBCLK counts

EPwm1Regs.TBPHS.half.TBPHS = 0; // Set Phase register to zero

EPwm1Regs.TBCTL.bit.CTRMODE = TB_COUNT_UPDOWN; // Symmetrical mode

EPwm1Regs.TBCTL.bit.PHSEN = TB_DISABLE; // Master module

EPwm1Regs.TBCTL.bit.PRDLD = TB_SHADOW;

EPwm1Regs.TBCTL.bit.SYNCOSEL = TB_CTR_ZERO; // Sync down-stream module

EPwm1Regs.TBCTL.bit.HSPCLKDIV = TB_DIV1; // Clock ratio to SYSCLKOUT

EPwm1Regs.TBCTL.bit.CLKDIV = TB_DIV1;

EPwm1Regs.TBPHS.half.TBPHS = 0; // Set Phase register to zero

EPwm1Regs.TBCTL.bit.CTRMODE = TB_COUNT_UPDOWN; // Symmetrical mode

EPwm1Regs.TBCTL.bit.PHSEN = TB_DISABLE; // Master module

EPwm1Regs.TBCTL.bit.PRDLD = TB_SHADOW;

EPwm1Regs.TBCTL.bit.SYNCOSEL = TB_CTR_ZERO; // Sync down-stream module

EPwm1Regs.TBCTL.bit.HSPCLKDIV = TB_DIV1; // Clock ratio to SYSCLKOUT

EPwm1Regs.TBCTL.bit.CLKDIV = TB_DIV1;

EPwm1Regs.CMPCTL.bit.SHDWAMODE = CC_SHADOW;

EPwm1Regs.CMPCTL.bit.SHDWBMODE = CC_SHADOW;

EPwm1Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm1Regs.CMPCTL.bit.LOADBMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm1Regs.AQCTLA.bit.CAU = AQ_SET; // set actions for EPWM1A

EPwm1Regs.AQCTLA.bit.CAD = AQ_CLEAR;

EPwm1Regs.DBCTL.bit.OUT_MODE = DB_FULL_ENABLE; // enable Dead-band module

EPwm1Regs.DBCTL.bit.POLSEL = DB_ACTV_HIC; // Active Hi complementary

EPwm1Regs.DBFED = 200; // FED = 20 TBCLKs

EPwm1Regs.DBRED = 200; // RED = 20 TBCLKs

EPwm1Regs.CMPA.half.CMPA = 3750; // adjust duty for output EPWM1A

EPwm1Regs.CMPCTL.bit.SHDWBMODE = CC_SHADOW;

EPwm1Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm1Regs.CMPCTL.bit.LOADBMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm1Regs.AQCTLA.bit.CAU = AQ_SET; // set actions for EPWM1A

EPwm1Regs.AQCTLA.bit.CAD = AQ_CLEAR;

EPwm1Regs.DBCTL.bit.OUT_MODE = DB_FULL_ENABLE; // enable Dead-band module

EPwm1Regs.DBCTL.bit.POLSEL = DB_ACTV_HIC; // Active Hi complementary

EPwm1Regs.DBFED = 200; // FED = 20 TBCLKs

EPwm1Regs.DBRED = 200; // RED = 20 TBCLKs

EPwm1Regs.CMPA.half.CMPA = 3750; // adjust duty for output EPWM1A

EPwm1Regs.ETSEL.bit.SOCAEN = 1; // Enable SOC on A group

EPwm1Regs.ETSEL.bit.SOCASEL = 4; // Select SOC from from CPMA on upcount

EPwm1Regs.ETPS.bit.SOCAPRD = 1; // Generate pulse on 1st event

}

EPwm1Regs.ETSEL.bit.SOCASEL = 4; // Select SOC from from CPMA on upcount

EPwm1Regs.ETPS.bit.SOCAPRD = 1; // Generate pulse on 1st event

}

void InitEPwm2Example()

{

EPwm2Regs.TBPRD = 7500; // Period = 900 TBCLK counts

EPwm2Regs.TBPHS.half.TBPHS = 5000; // Phase = 300/900 * 360 = 120 deg

EPwm2Regs.TBCTL.bit.CTRMODE = TB_COUNT_UPDOWN; // Symmetrical mode

EPwm2Regs.TBCTL.bit.PHSEN = TB_ENABLE; // Slave module

EPwm2Regs.TBCTL.bit.PHSDIR = TB_DOWN; // Count DOWN on sync (=120 deg)

EPwm2Regs.TBCTL.bit.PRDLD = TB_SHADOW;

EPwm2Regs.TBCTL.bit.SYNCOSEL = TB_SYNC_IN; // sync flow-through

EPwm2Regs.TBCTL.bit.HSPCLKDIV = TB_DIV1; // Clock ratio to SYSCLKOUT

EPwm2Regs.TBCTL.bit.CLKDIV = TB_DIV1;

{

EPwm2Regs.TBPRD = 7500; // Period = 900 TBCLK counts

EPwm2Regs.TBPHS.half.TBPHS = 5000; // Phase = 300/900 * 360 = 120 deg

EPwm2Regs.TBCTL.bit.CTRMODE = TB_COUNT_UPDOWN; // Symmetrical mode

EPwm2Regs.TBCTL.bit.PHSEN = TB_ENABLE; // Slave module

EPwm2Regs.TBCTL.bit.PHSDIR = TB_DOWN; // Count DOWN on sync (=120 deg)

EPwm2Regs.TBCTL.bit.PRDLD = TB_SHADOW;

EPwm2Regs.TBCTL.bit.SYNCOSEL = TB_SYNC_IN; // sync flow-through

EPwm2Regs.TBCTL.bit.HSPCLKDIV = TB_DIV1; // Clock ratio to SYSCLKOUT

EPwm2Regs.TBCTL.bit.CLKDIV = TB_DIV1;

EPwm2Regs.CMPCTL.bit.SHDWAMODE = CC_SHADOW;

EPwm2Regs.CMPCTL.bit.SHDWBMODE = CC_SHADOW;

EPwm2Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm2Regs.CMPCTL.bit.LOADBMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm2Regs.AQCTLA.bit.CAU = AQ_SET; // set actions for EPWM2A

EPwm2Regs.AQCTLA.bit.CAD = AQ_CLEAR;

EPwm2Regs.DBCTL.bit.OUT_MODE = DB_FULL_ENABLE; // enable Dead-band module

EPwm2Regs.DBCTL.bit.POLSEL = DB_ACTV_HIC; // Active Hi Complementary

EPwm2Regs.DBFED = 20; // FED = 20 TBCLKs

EPwm2Regs.DBRED = 20; // RED = 20 TBCLKs

EPwm2Regs.CMPA.half.CMPA = 3750; // adjust duty for output EPWM1A

EPwm2Regs.CMPCTL.bit.SHDWBMODE = CC_SHADOW;

EPwm2Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm2Regs.CMPCTL.bit.LOADBMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm2Regs.AQCTLA.bit.CAU = AQ_SET; // set actions for EPWM2A

EPwm2Regs.AQCTLA.bit.CAD = AQ_CLEAR;

EPwm2Regs.DBCTL.bit.OUT_MODE = DB_FULL_ENABLE; // enable Dead-band module

EPwm2Regs.DBCTL.bit.POLSEL = DB_ACTV_HIC; // Active Hi Complementary

EPwm2Regs.DBFED = 20; // FED = 20 TBCLKs

EPwm2Regs.DBRED = 20; // RED = 20 TBCLKs

EPwm2Regs.CMPA.half.CMPA = 3750; // adjust duty for output EPWM1A

}

void InitEPwm3Example()

{

{

EPwm3Regs.TBPRD = 7500; // Period = 900 TBCLK counts

EPwm3Regs.TBPHS.half.TBPHS = 5000; // Phase = 300/900 * 360 = 120 deg

EPwm3Regs.TBCTL.bit.CTRMODE = TB_COUNT_UPDOWN; // Symmetrical mode

EPwm3Regs.TBCTL.bit.PHSEN = TB_ENABLE; // Slave module

EPwm3Regs.TBCTL.bit.PHSDIR = TB_UP; // Count UP on sync (=240 deg)

EPwm3Regs.TBCTL.bit.PRDLD = TB_SHADOW;

EPwm3Regs.TBCTL.bit.SYNCOSEL = TB_SYNC_IN; // sync flow-through

EPwm3Regs.TBCTL.bit.HSPCLKDIV = TB_DIV1; // Clock ratio to SYSCLKOUT

EPwm3Regs.TBCTL.bit.CLKDIV = TB_DIV1;

EPwm3Regs.TBPHS.half.TBPHS = 5000; // Phase = 300/900 * 360 = 120 deg

EPwm3Regs.TBCTL.bit.CTRMODE = TB_COUNT_UPDOWN; // Symmetrical mode

EPwm3Regs.TBCTL.bit.PHSEN = TB_ENABLE; // Slave module

EPwm3Regs.TBCTL.bit.PHSDIR = TB_UP; // Count UP on sync (=240 deg)

EPwm3Regs.TBCTL.bit.PRDLD = TB_SHADOW;

EPwm3Regs.TBCTL.bit.SYNCOSEL = TB_SYNC_IN; // sync flow-through

EPwm3Regs.TBCTL.bit.HSPCLKDIV = TB_DIV1; // Clock ratio to SYSCLKOUT

EPwm3Regs.TBCTL.bit.CLKDIV = TB_DIV1;

EPwm3Regs.CMPCTL.bit.SHDWAMODE = CC_SHADOW;

EPwm3Regs.CMPCTL.bit.SHDWBMODE = CC_SHADOW;

EPwm3Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm3Regs.CMPCTL.bit.LOADBMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm3Regs.AQCTLA.bit.CAU = AQ_SET; // set actions for EPWM3Ai

EPwm3Regs.AQCTLA.bit.CAD = AQ_CLEAR;

EPwm3Regs.DBCTL.bit.OUT_MODE = DB_FULL_ENABLE; // enable Dead-band module

EPwm3Regs.DBCTL.bit.POLSEL = DB_ACTV_HIC; // Active Hi complementary

EPwm3Regs.DBFED = 20; // FED = 20 TBCLKs

EPwm3Regs.DBRED = 20; // RED = 20 TBCLKs

EPwm3Regs.CMPA.half.CMPA = 3750; // adjust duty for output EPWM1A

EPwm3Regs.CMPCTL.bit.SHDWBMODE = CC_SHADOW;

EPwm3Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm3Regs.CMPCTL.bit.LOADBMODE = CC_CTR_ZERO; // load on CTR=Zero

EPwm3Regs.AQCTLA.bit.CAU = AQ_SET; // set actions for EPWM3Ai

EPwm3Regs.AQCTLA.bit.CAD = AQ_CLEAR;

EPwm3Regs.DBCTL.bit.OUT_MODE = DB_FULL_ENABLE; // enable Dead-band module

EPwm3Regs.DBCTL.bit.POLSEL = DB_ACTV_HIC; // Active Hi complementary

EPwm3Regs.DBFED = 20; // FED = 20 TBCLKs

EPwm3Regs.DBRED = 20; // RED = 20 TBCLKs

EPwm3Regs.CMPA.half.CMPA = 3750; // adjust duty for output EPWM1A

}

__interrupt void adc_isr(void)

{

Voltage1[ConversionCount] = AdcRegs.ADCRESULT0 >>4;

Voltage2[ConversionCount] = AdcRegs.ADCRESULT1 >>4;

{

Voltage1[ConversionCount] = AdcRegs.ADCRESULT0 >>4;

Voltage2[ConversionCount] = AdcRegs.ADCRESULT1 >>4;

// If 40 conversions have been logged, start over

if(ConversionCount == 9)

{

ConversionCount = 0;

}

else

{

ConversionCount++;

}

if(ConversionCount == 9)

{

ConversionCount = 0;

}

else

{

ConversionCount++;

}

// Reinitialize for next ADC sequence

AdcRegs.ADCTRL2.bit.RST_SEQ1 = 1; // Reset SEQ1

AdcRegs.ADCST.bit.INT_SEQ1_CLR = 1; // Clear INT SEQ1 bit

PieCtrlRegs.PIEACK.all = PIEACK_GROUP1; // Acknowledge interrupt to PIE

AdcRegs.ADCTRL2.bit.RST_SEQ1 = 1; // Reset SEQ1

AdcRegs.ADCST.bit.INT_SEQ1_CLR = 1; // Clear INT SEQ1 bit

PieCtrlRegs.PIEACK.all = PIEACK_GROUP1; // Acknowledge interrupt to PIE

return;

}

}

//===========================================================================

// No more.

//===========================================================================

// No more.

//===========================================================================

likai hu:

回复 HeiHei:

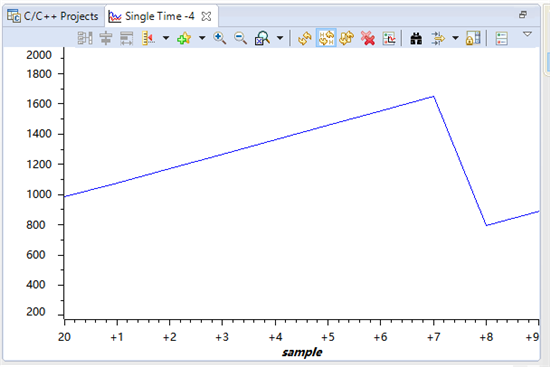

不好意思啊,我用的是ti的28335,现在通过pwm触发adc,当我采集的是恒定电压时,通过观察结果寄存器和数组发现采集的量是正确的,但是当我用函数信号发生器产生一个正弦或者锯齿波时,通过ccs6.0自带的graph无法观察到正确的波形,

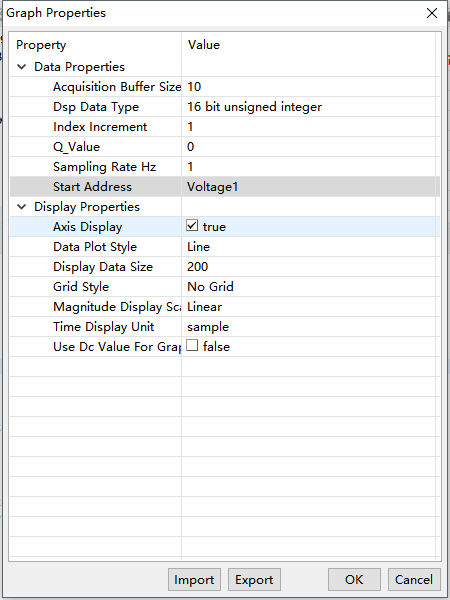

这是我具体的参数设置, 我定义的数组是无符号整型的,

我定义的数组是无符号整型的,

这是我寄存器的配置,

这是我寄存器的配置,

最后得出的波形却是这个样子。。

不知道是哪里出错了,希望大神帮忙看看

TI中文支持网

TI中文支持网