最近在搞变频器,用的是28035,不知道这个模块的寄存器是干什么用的?

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 1;

EPwm2Regs.PCCTL.bit.CHPEN = 1;

EPwm3Regs.PCCTL.bit.CHPEN = 1;

程序中是这样配置的,看输出DSP主控板的输出波形为每一道PWM波的高电平都被斩为七份(大概是)高低脉冲,但是经过驱动板上面的光耦隔离后,IGBT的门极PWM波变正常了,跟没有配置这个寄存器的PWM 是一样的(每一道PWM波的高电平一直为高,不再有被斩的效果)……

我们变频器遇到的问题是发热严重,载波频率为4K,2.2KW的,匹配型号的电机空载运行,变频器温升可达10~12℃,程序为上面的配置……

本以为不配置这个寄存器,温升会下降,我做如下修改:

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 0;

EPwm2Regs.PCCTL.bit.CHPEN = 0;

EPwm3Regs.PCCTL.bit.CHPEN = 0;

没想到,修改后,温升又增加了2~3℃,这是为什么呢?对于修改前的程序,IGBT门极波形和DSP输出波形不同,又是为什么呢?

Blake Ma:

您好,

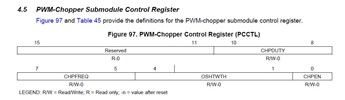

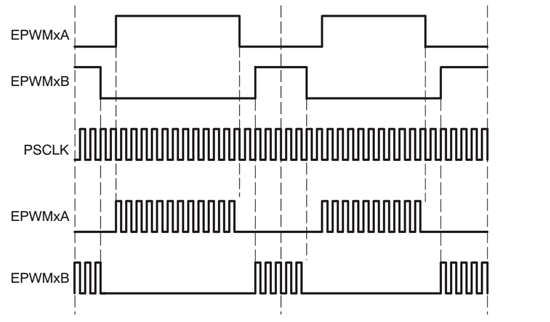

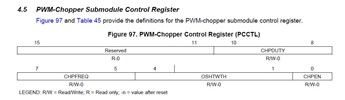

PCCTL 这个寄存器的作用就是对 ePWM 模块的 Chopper (斩波)功能进行配置,斩波的功能的作用效果如下图所示:

(1)暂时无法从您的描述中得出为什么变频器温度会升高;

(2)至于 IGBT 的门极电压波形与 C2000 输出的电压波形不同,可能是因为斩波的频率超过了光耦所能传输的频率,因而被过滤掉了;具体请查看所使用的光耦的最高传输速率,与所使用的斩波频率进行比较。

最近在搞变频器,用的是28035,不知道这个模块的寄存器是干什么用的?

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 1;

EPwm2Regs.PCCTL.bit.CHPEN = 1;

EPwm3Regs.PCCTL.bit.CHPEN = 1;

程序中是这样配置的,看输出DSP主控板的输出波形为每一道PWM波的高电平都被斩为七份(大概是)高低脉冲,但是经过驱动板上面的光耦隔离后,IGBT的门极PWM波变正常了,跟没有配置这个寄存器的PWM 是一样的(每一道PWM波的高电平一直为高,不再有被斩的效果)……

我们变频器遇到的问题是发热严重,载波频率为4K,2.2KW的,匹配型号的电机空载运行,变频器温升可达10~12℃,程序为上面的配置……

本以为不配置这个寄存器,温升会下降,我做如下修改:

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 0;

EPwm2Regs.PCCTL.bit.CHPEN = 0;

EPwm3Regs.PCCTL.bit.CHPEN = 0;

没想到,修改后,温升又增加了2~3℃,这是为什么呢?对于修改前的程序,IGBT门极波形和DSP输出波形不同,又是为什么呢?

heshang xiao:

回复 Blake Ma:

Blake Ma 您好!谢谢您的回答,对我很有帮助!我想追问一下:

28035 ePWM模块中的PCCTL这样一个寄存器,对输出PWM波的高电平进行斩波,有什么作用和意义?一般在什么应用中打开并设置该寄存器,会有什么样的效果?

因为我暂时不明白在该电机驱动程序中,他这样设置是为何……

最近在搞变频器,用的是28035,不知道这个模块的寄存器是干什么用的?

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 1;

EPwm2Regs.PCCTL.bit.CHPEN = 1;

EPwm3Regs.PCCTL.bit.CHPEN = 1;

程序中是这样配置的,看输出DSP主控板的输出波形为每一道PWM波的高电平都被斩为七份(大概是)高低脉冲,但是经过驱动板上面的光耦隔离后,IGBT的门极PWM波变正常了,跟没有配置这个寄存器的PWM 是一样的(每一道PWM波的高电平一直为高,不再有被斩的效果)……

我们变频器遇到的问题是发热严重,载波频率为4K,2.2KW的,匹配型号的电机空载运行,变频器温升可达10~12℃,程序为上面的配置……

本以为不配置这个寄存器,温升会下降,我做如下修改:

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 0;

EPwm2Regs.PCCTL.bit.CHPEN = 0;

EPwm3Regs.PCCTL.bit.CHPEN = 0;

没想到,修改后,温升又增加了2~3℃,这是为什么呢?对于修改前的程序,IGBT门极波形和DSP输出波形不同,又是为什么呢?

Blake Ma:

回复 heshang xiao:

在电机驱动应用中,有时会需要对 PWM 信号进行进一步的调制,用调制后的信号控制电机的驱动芯片,而这种调制功能就可以通过“斩波”来实现。如果您有机会测量 TI 的 DRV8312 EVM 板上的 6 路 PWM 控制信号,会发现在控制 BLDC 的示例工程执行的过程中有 3 路信号是经过调制的 PWM 。

最近在搞变频器,用的是28035,不知道这个模块的寄存器是干什么用的?

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 1;

EPwm2Regs.PCCTL.bit.CHPEN = 1;

EPwm3Regs.PCCTL.bit.CHPEN = 1;

程序中是这样配置的,看输出DSP主控板的输出波形为每一道PWM波的高电平都被斩为七份(大概是)高低脉冲,但是经过驱动板上面的光耦隔离后,IGBT的门极PWM波变正常了,跟没有配置这个寄存器的PWM 是一样的(每一道PWM波的高电平一直为高,不再有被斩的效果)……

我们变频器遇到的问题是发热严重,载波频率为4K,2.2KW的,匹配型号的电机空载运行,变频器温升可达10~12℃,程序为上面的配置……

本以为不配置这个寄存器,温升会下降,我做如下修改:

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 0;

EPwm2Regs.PCCTL.bit.CHPEN = 0;

EPwm3Regs.PCCTL.bit.CHPEN = 0;

没想到,修改后,温升又增加了2~3℃,这是为什么呢?对于修改前的程序,IGBT门极波形和DSP输出波形不同,又是为什么呢?

Eric Fu:

回复 heshang xiao:

heshang xiao 你好,

"The PWM-chopper submodule allows a high-frequency carrier signal to modulate the PWM waveformgenerated by the action-qualifier and dead-band submodules. This capability is important if you needpulse transformer-based gate drivers to control the power switching elements.”

上面的一段话说明了Chopper的作用,在一些脉冲变压器驱动的的场景中用到。

最近在搞变频器,用的是28035,不知道这个模块的寄存器是干什么用的?

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 1;

EPwm2Regs.PCCTL.bit.CHPEN = 1;

EPwm3Regs.PCCTL.bit.CHPEN = 1;

程序中是这样配置的,看输出DSP主控板的输出波形为每一道PWM波的高电平都被斩为七份(大概是)高低脉冲,但是经过驱动板上面的光耦隔离后,IGBT的门极PWM波变正常了,跟没有配置这个寄存器的PWM 是一样的(每一道PWM波的高电平一直为高,不再有被斩的效果)……

我们变频器遇到的问题是发热严重,载波频率为4K,2.2KW的,匹配型号的电机空载运行,变频器温升可达10~12℃,程序为上面的配置……

本以为不配置这个寄存器,温升会下降,我做如下修改:

EPwm1Regs.PCCTL.bit.CHPDUTY = 6;

EPwm2Regs.PCCTL.bit.CHPDUTY = 6;

EPwm3Regs.PCCTL.bit.CHPDUTY = 6;

EPwm1Regs.PCCTL.bit.CHPFREQ = 7;

EPwm2Regs.PCCTL.bit.CHPFREQ = 7;

EPwm3Regs.PCCTL.bit.CHPFREQ = 7;

EPwm1Regs.PCCTL.bit.OSHTWTH = 15;

EPwm2Regs.PCCTL.bit.OSHTWTH = 15;

EPwm3Regs.PCCTL.bit.OSHTWTH = 15;

EPwm1Regs.PCCTL.bit.CHPEN = 0;

EPwm2Regs.PCCTL.bit.CHPEN = 0;

EPwm3Regs.PCCTL.bit.CHPEN = 0;

没想到,修改后,温升又增加了2~3℃,这是为什么呢?对于修改前的程序,IGBT门极波形和DSP输出波形不同,又是为什么呢?

heshang xiao:

回复 Blake Ma:

您好,Blake Ma,我想再问下关于这个斩波的问题,变频器程序中,打开了斩波配置,

EPwm1Regs.PCCTL.bit.CHPDUTY = 6; EPwm2Regs.PCCTL.bit.CHPDUTY = 6; EPwm3Regs.PCCTL.bit.CHPDUTY = 6; EPwm1Regs.PCCTL.bit.CHPFREQ = 7; EPwm2Regs.PCCTL.bit.CHPFREQ = 7; EPwm3Regs.PCCTL.bit.CHPFREQ = 7; EPwm1Regs.PCCTL.bit.OSHTWTH = 15; EPwm2Regs.PCCTL.bit.OSHTWTH = 15; EPwm3Regs.PCCTL.bit.OSHTWTH = 15; EPwm1Regs.PCCTL.bit.CHPEN = 1; EPwm2Regs.PCCTL.bit.CHPEN = 1; EPwm3Regs.PCCTL.bit.CHPEN = 1;

程序配置还是和最上面的一样,我的程序的高低电平和IGBT侧的脉冲刚好是反向的,我在担心打开这个斩波控制后,如果这些斩波未被过滤掉,这样在应用的过程中,会不会IGBT瞬间就被直通了呢?

我是这样理解的,不知道是否正确~~

TI中文支持网

TI中文支持网